V-TORQ

Variable Speed Drive

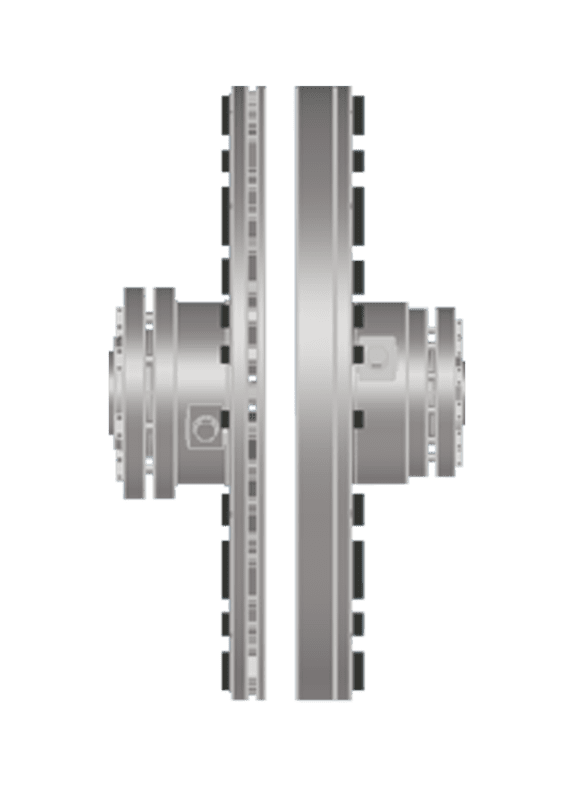

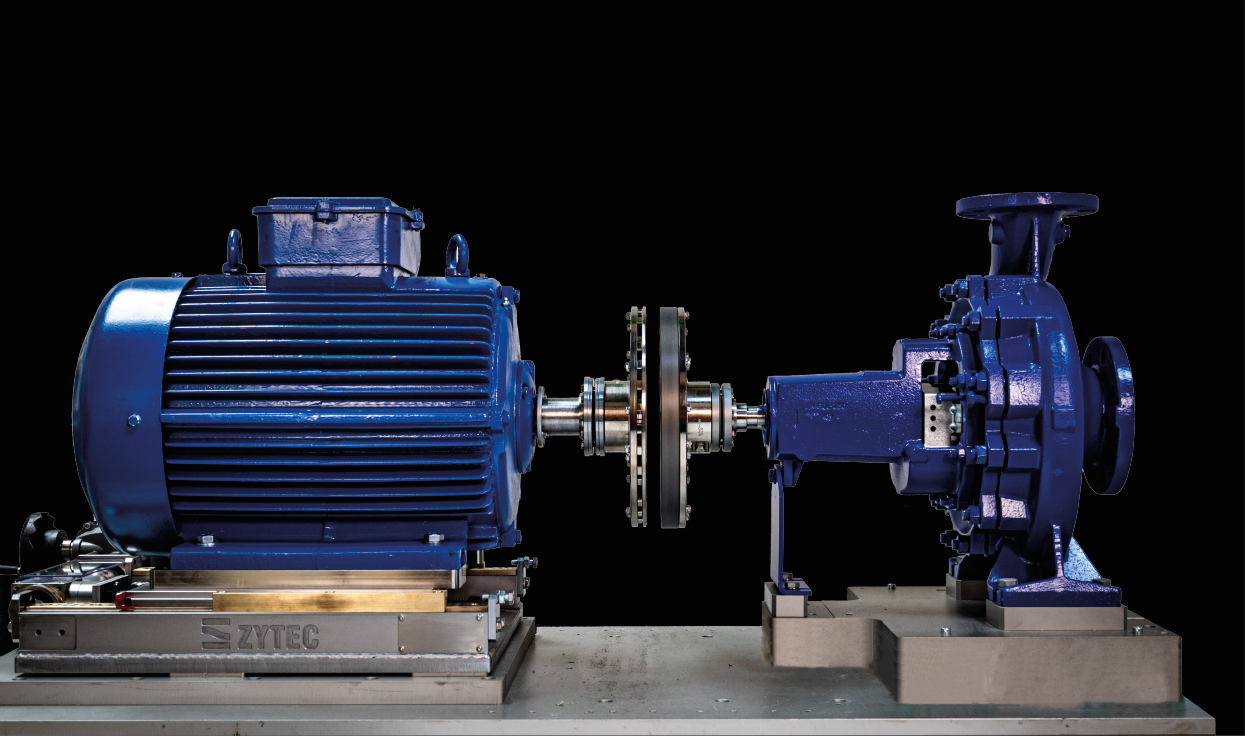

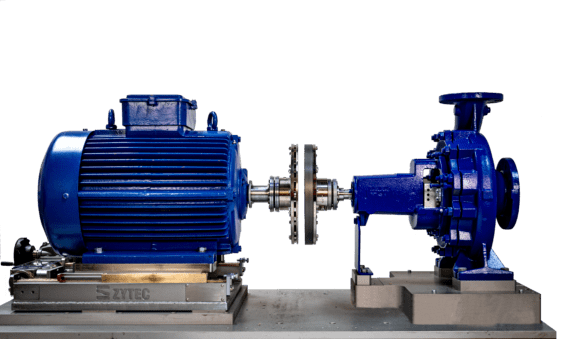

V-TORQ

Non-Contact Variable Speed Drive for Variable Speed Control

The V-TORQ Non-Contact Variable Speed Drive is designed for applications where the speed of the driven side needs to be adjusted manually or automatically during operation. V-TORQ combines the benefits of non-contact power transmission with simple speed control, making it ideal for controlling flow or pressure in pumps and fans, with energy savings of up to 50%.

Key Features

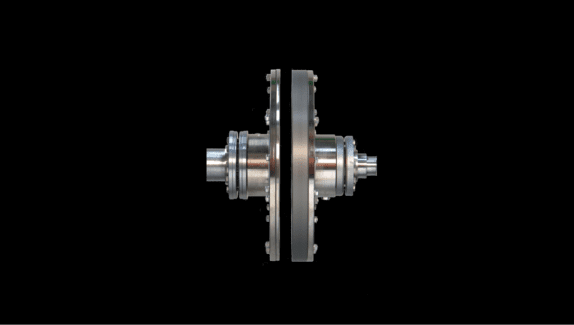

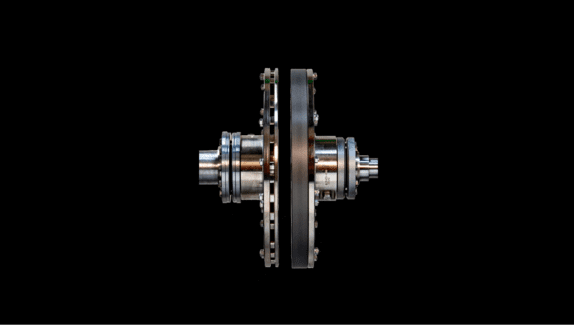

- V-TORQ is a combination of an A-TORQ and a Motor Sliding Base (MSB)

- Suitable for motor power from 7.5 kW to 375 kW

- Speeds up to 3,600 rpm

- Compatible with motors built before 1999

- ATEX-compliant

- No physical contact between motor and driven equipment

- Suitable for pumps, fans, and compressors

What problems does V-TORQ solve?

Energy Savings

By vary the speed of the pump or fan with a V-TORQ, significant energy savings can be achieved:

- Immediate energy savings of up to 50%

- Energy-wasting throttling valves can be fully opened

Result: Lower energy costs and reduced CO₂ emissions.

Less Maintenance

V-TORQ prevents mechanical wear thanks to its non-contact design:

- Speed control without shaft current through bearings

- No need for laser alignment

- Less malfunctions and mechanical failures

Result: A simple, low-maintenance variable drive system that keeps your installation reliable and efficient.

Less Repairs

Thanks to the adjustable coupling and damping characteristics, V-TORQ protects components from overload:

- Strong shock load damping (acts as a mechanical soft starter)

- Motor load is optimally matched to process requirements

- No harmonic distortion or EMC interference

- Extended service life of bearings, seals, and motors

Result: Lower repair costs, longer lifespan of key components, and improved system reliability.

Less Downtime

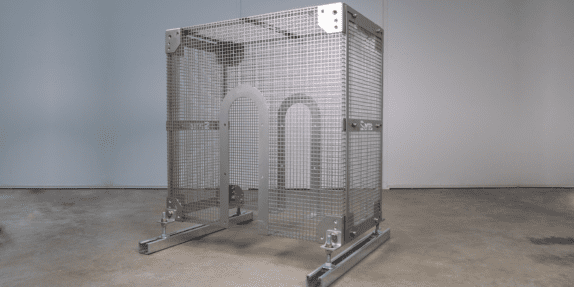

V-TORQ reduces the risk of unplanned downtime and simplifies maintenance tasks:

- Back pull-out pumps are easier to service with up to 200 mm of retraction via the MSB

- No spacer required

- No complex realignment necessary

- Speed can be adjusted without interrupting production

- Ideal for seasonal settings (e.g. summer/winter) or integration into process automation

Result: Increased uptime, faster maintenance, and greater availability

Do you want to conquer the world with us?

Danny van Nielen

Business Development Director