F-TORQ

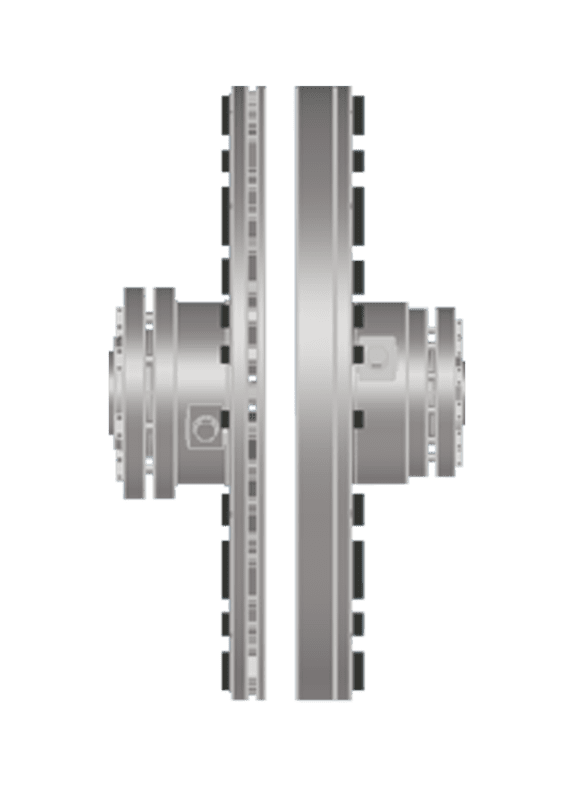

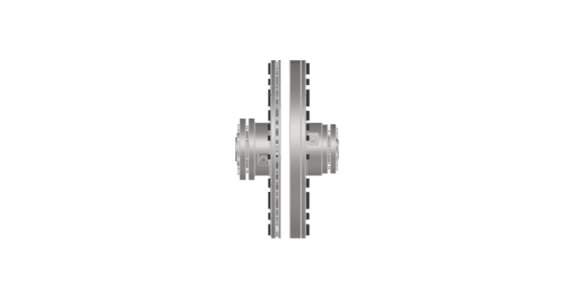

Fixed speed coupling

F-TORQ

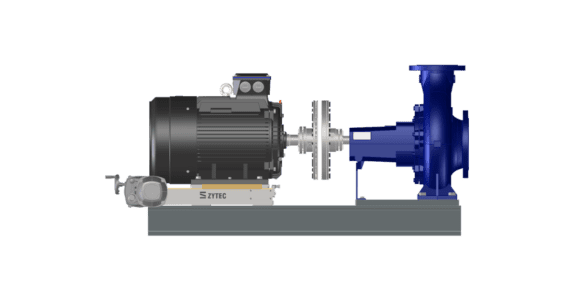

The unique non-contact drive for fixed speed

- Since the non-contact drive causes no more vibrations, the installation becomes significantly more robust and reliable.

- Laser alignment is no longer required because misalignment up to 2mm causes no loss of function.

- The F-TORQ can also be used in combination with a VFD controlling the speed of the motor.

- The standard range of F-TORQ covers motors from 3 to 375 kW and speeds of 750rpm to 3.600 rpm. The customised range of the F-TORQ is up to 2MW depending on the application.

Why the F-TORQ?

This non-contact drive will help you reduce and save on maintenance and make your installations reliable and future-proof.

Why the F-TORQ is the perfect solution for you:

- The F-TORQ is an easy retrofit for all kind of physical contact couplings like i.e. EUPEX flexible coupling, Omega band coupling, teeth coupling, pin coupling, flexible disc couplings, etc.

- It can also replace a fluid coupling which is used for the starting process of loads with high inertia, like fans.

- The motor is protected from overload and high amperage during the start process and creates a more stable power grid with a reduced risk on voltage dips.

- This non-contact drive will help you reduce and save on maintenance and make your installations reliable and future-proof.

- The total cost of ownership decreases, while your non-contact drive ensures a smooth and uninterrupted process with minimal downtime.

What does the F-Torq fixed speed non-contact drive do for you:

- Using Zytec F-TORQ results in a lower total cost of ownership for your entire installation.

- You will see immediate savings on the hidden costs.

- The installation of the non-contact magnetic coupling results in reduced wear on both the motor and load side: shock loads are dampened; misalignment damage is eliminated.

- Also cold start problems are reduced or even eliminated due to torque limitation from ramp-up from start.

- Your preventive maintenance schedule can be modified. This non-contact drive is robust and requires no maintenance;

- This all adds up to longer uptime, certainly by reducing unplanned stoppages for repairs.

With F-TORQ the total cost of ownership decreases, while your non-contact drive ensures a smooth and uninterrupted process with minimal downtime.

The F-TORQ creates a drive with no physical contact between the shafts

- Unavoidable misalignment during operation becomes irrelevant.

- No laser alignment needed

- No shaft loads on the motor and load shaft.

- The root cause of failure of the bearing and seals is eliminated.

- The life span of the bearing of the motor is expanded to design life.

- The life span of seals is extended significantly.

- Vibrations are reduced up till 80%.

- A cushioned start and stop (mechanical soft starter).

Our Zytec Certified Partners will be pleased to assist you in selecting the correct non-contact drive for your installation and calculating the total cost of ownership and payback period.

Do you want to conquer the world with us?

Danny van Nielen

Business Development Director

Eliminate the root cause of failure

Although we live and work in exciting times with unique innovations, industrial companies sometimes have to hit the brakes. New and exciting technology solutions seem to be everywhere, but there is one big obstacle that slows the innovation process down:

- There is a general shortage of skilled staff (especially technical maintenance personnel) in complex industrial plants.

- How can we fill this so-called ‘workforce gap’ on short notice by eliminating the root cause of failure in industrial machines?

Smart, simple, often overlooked

One of the smartest (but often overlooked) solutions is simply eliminating maintenance needs as much as possible. This may seem easier said than done. But there really is a straightforward solution when industries review their pumps and couplings.

Using magnetic couplings will eliminate most of the causes of machine breakdowns and enhance the reliability of your machines. Magnetic couplings eliminate the root cause of many machines’ failure, resulting in low TCO and less waste of time and materials.

Read all about this in the Whitepaper ‘Eliminate the Root Cause of Failure’. Where we take a closer look at the solution of the magnetic couplings to:

- Eliminate the root cause of failures affecting your machines

- Find the missing piece of the puzzle to fill the workforce gap.